13th European Thermoforming Conference

13th European Thermoforming Conference

Demonstrating vacuum forming on 3D printed tools

Demonstrating vacuum forming on 3D printed tools

13th European Thermoforming Conference

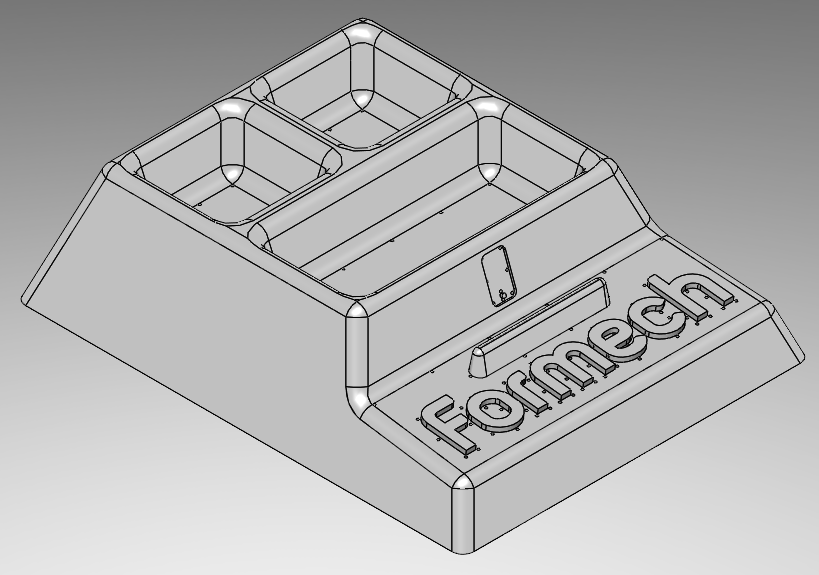

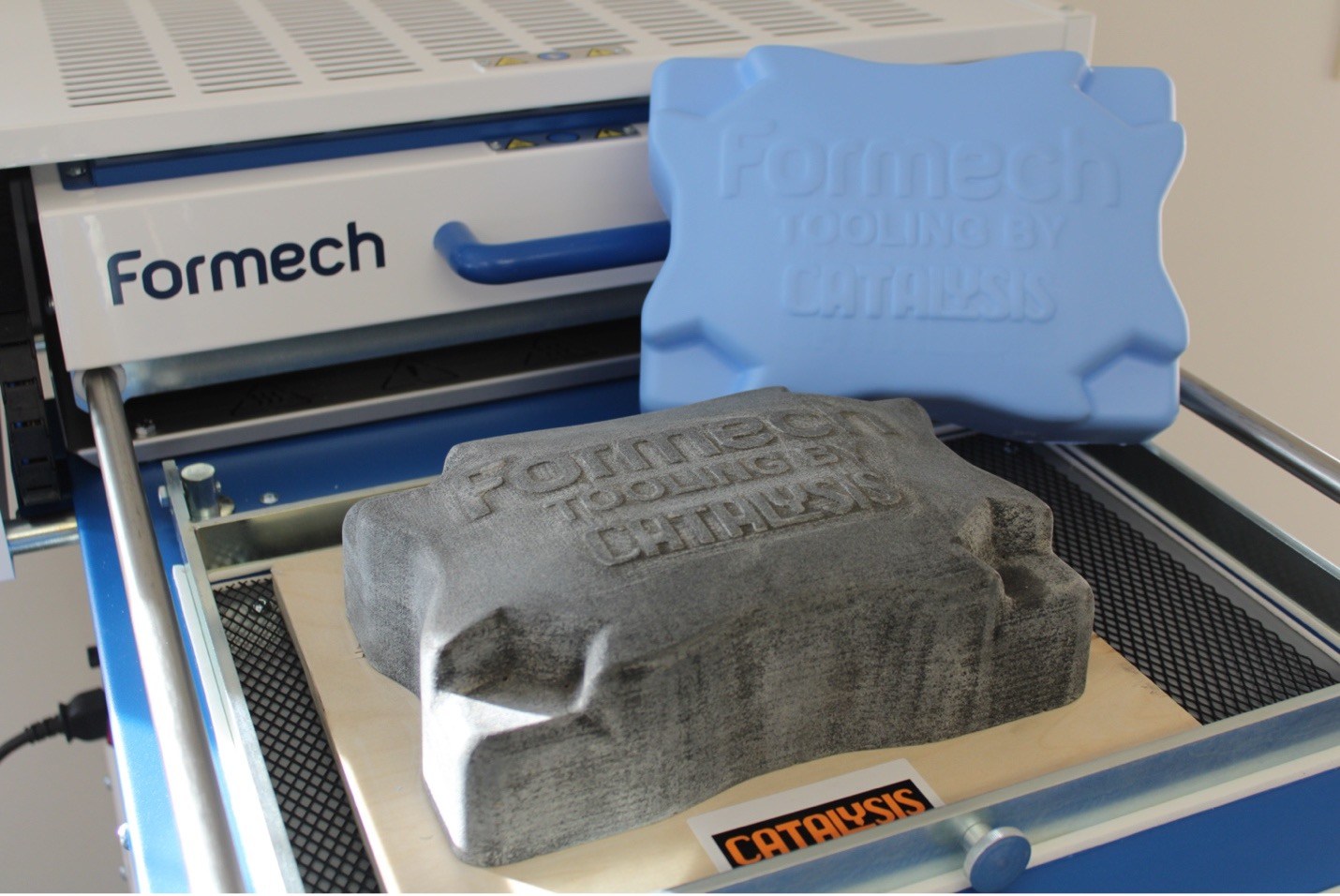

We are at the 13th European Thermoforming Conference in Amsterdam with our friends at Catalysis Additive Tooling. The Formech team are on the stand to demo how well the 508FS machine can vacuum form 3D printed tools, as well as… Formech 508FS vacuum forming machineCatalysis 3D printed tool ready for vacuum formingCatalysis 3D printed tool and its… Click on the thumbnails below to watch a Catalysis 3D printed tool being vacuum formed at the event:

Lesen Sie mehr

Opening Doors for Vacuum Forming

We recently visited our client Doorco, a leading innovator in the composite door industry, with a reputation for… Textured aluminium tool in use at Doorco Formed door skin detail at Doorco Door skins ready for the door assembly

Lesen Sie mehr

Visit 3S Systems at SIMTOS 2024, Korea

Looking for Vacuum Forming solutions in Korea? Our partner 3S Systems is attending the Seoul International Machinery… Formech 508FS

Lesen Sie mehr

HD750 to Eaton

We were thrilled to install an HD750 vacuum forming machine with a RP700 roller press for Eaton at their Titchfield… HD750 vacuum forming machine with a RP700 roller press Training Eaton staff members on the Formech HD750 vacuum forming machine

Lesen Sie mehr

Formech Marketing Bulletin: Stabiliser Installation

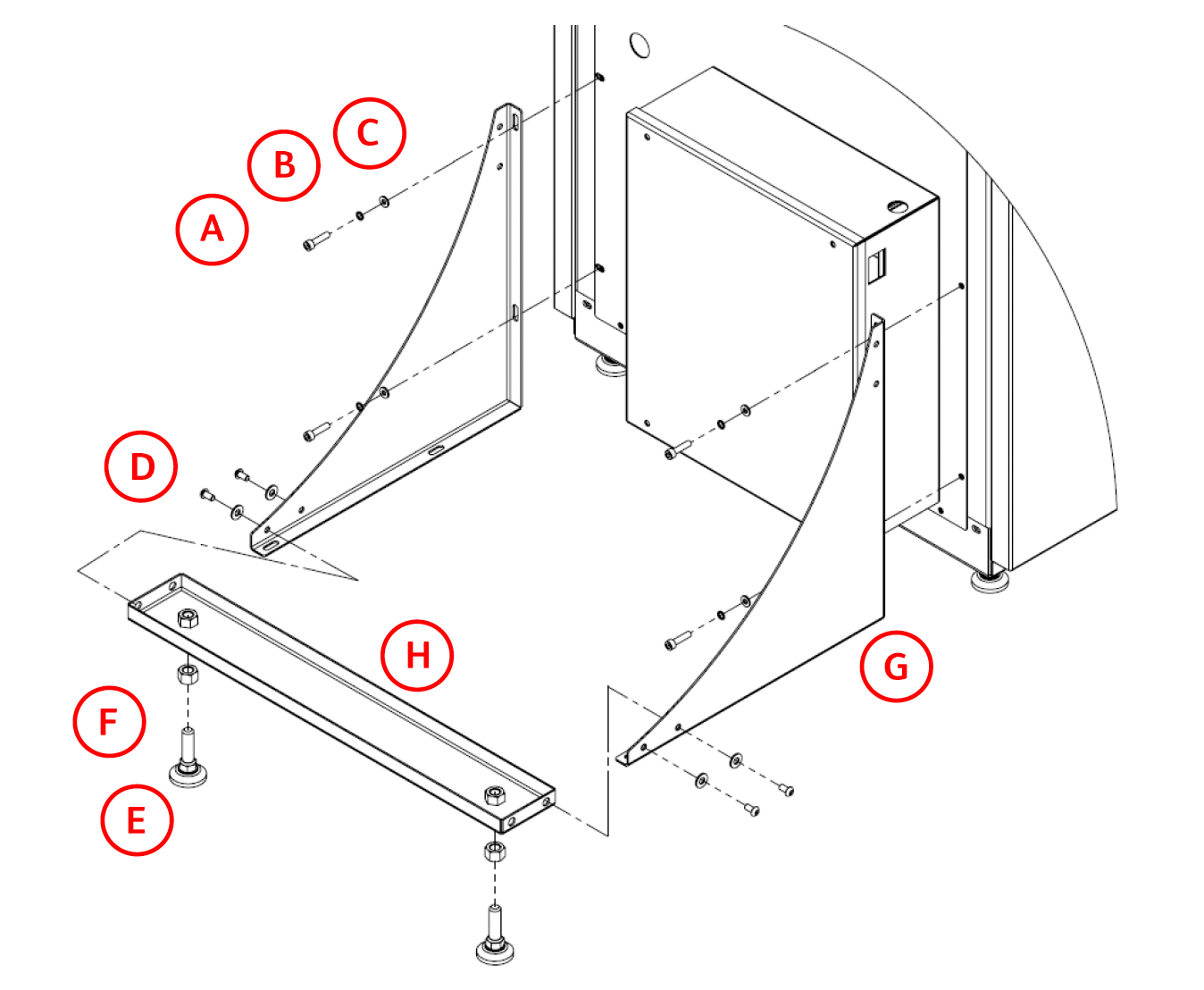

MB 24002 Rev B Formech 508FS vacuum former Formech 686 vacuum former (Single phase - US spec)

Lesen Sie mehr

Join Formech at the 2024 Southern Manufacturing show

Exciting news from Formech! Join us at the Southern Manufacturing show in Farnborough, UK February 6th-8th at stand…

Lesen Sie mehr

Formech 300DT How To Video Library

Welcome to Formech's 300DT How To video library. These videos show and describe how to use the 300DT's functions and…

Lesen Sie mehr

Formech Supporting Customers with Product Development Resources

The Proof of Concept program (POC) is a low cost low risk opportunity to take the first step into taking an idea and…

Lesen Sie mehr

Formech’s Proof of Concept Program continues making progress with initial tool design

Are you new to vacuum forming? Do you need help with tool design? Watch our video for more details:

Lesen Sie mehr

Formech works with Catalysis to provide existing and future customers with prototype and production level tooling solutions

Catalysis’ unique and disruptive technology allows them to provide tooling in half the time and at half the cost of…

Lesen Sie mehr

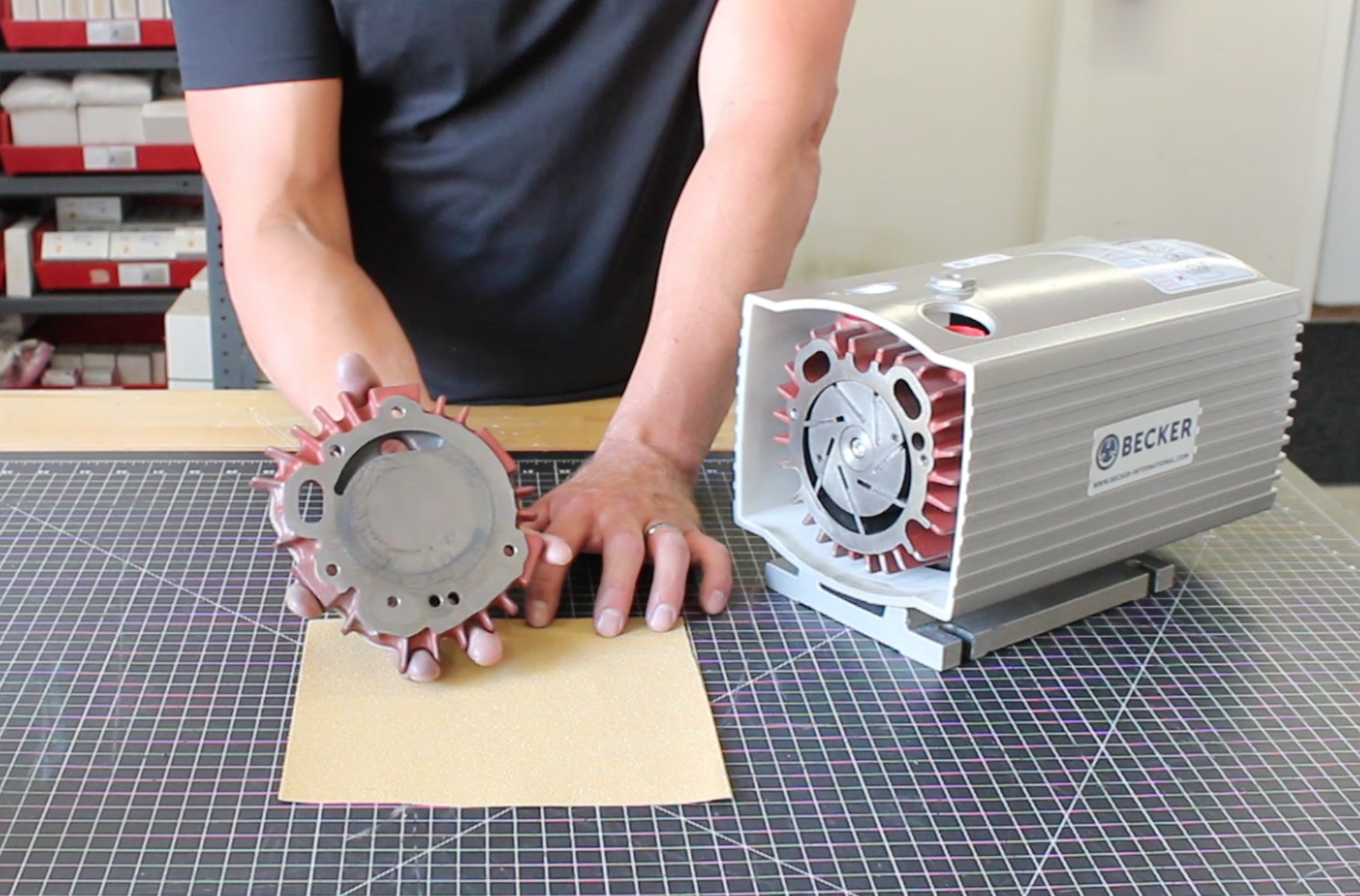

How-to clean the Becker Dry Vacuum Pump on your Formech machine

Dry systems do not like moisture and they can get seized up due to oxidation exposure. Regular check-ups and cleaning…

Lesen Sie mehr

Making Boba Fett's body armours with Formech 686

Meet Luis Sumano, owner of MinuteFett and creator of amazing body armors. Luis first started recreating Boba Fett…

Lesen Sie mehr